The Paramount Process

It’s simple. We have immense pride in our work and our smart team members work hard to create incredible projects. Our team is built on technical problem solving and bringing solutions the table.

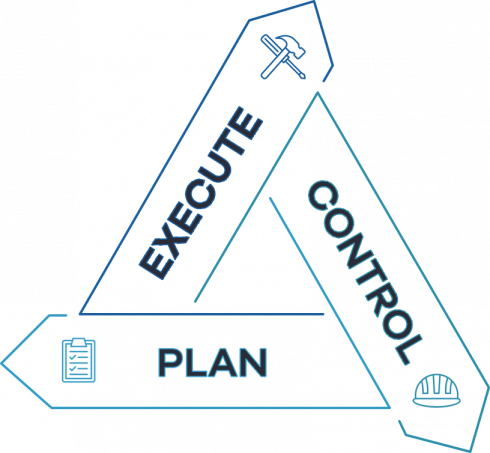

We complete projects and have a system that includes a detailed plan, processes in place to execute at a high level, and controls in place to create incredible quality and safety on a job.

Problem Solving

We uncover the unknowns before the job starts and deliver a detailed scope of work that includes a comprehensive summary of work.

Effective teamwork

We demand a lot from our foreman and hand select your team based on the best fit for your project.

Quality & Safety

We develop a unique quality plan for each project and safety is embedded into our culture.

Benefits

We remain true to the same principles that have guided our leadership team through nearly 60 years of specified industry experience. Providing superior service to our clients, putting safety first, creating opportunities for our people, and delivering exceptional work.

Leadership Team

Meet the think tank behind solving problems for the restoration industry. The Paramount leadership team operates with high moral and work ethic. With years of industry experience, our executives specialize in thinking creatively around solutions to best meet your project needs.

Kristopher Houger, CEO

Jason Travers, Superintendent of Southern California Operations

Mike Hubbard, Sales Account Manager of Los Angeles

Project Planning

We want to uncover the unknowns before the job starts and deliver a detailed scope of work that includes a comprehensive summary of work. In the project planning phases we enjoy detail so we can tailor a project to customer constraints.

In the ever demanding work environment we “think” and design for client’s needs:

Schedules

- Fast track projects

- Weekend /night shifts to allow for keeping buildings and parking structures open while working

Client Environment

- Engineering Noise and loud work

- Use of Low odor and VOC compliant materials

Job Specific Plans

- Traffic flow when working in parking garages

- Debris storage/ material storage/ work flow

Project Execution

Once the project is started there are several items we include in order to execute at a high level.

Foreman Selection

We demand a lot from our foreman. These are the front line leaders who make a project once it starts. On each project management hand selects the foreman for the best fit to a project based on experience and demands of the project. A few of the items they do at a high level daily:

• daily huddle and safety stretch

• daily communication with customer

• daily weather and wind monitoring

• management of public/worker safety

• daily job log and job tracking

We have a track record of delivering.

Our sales team provides:

- Weekly meeting minutes

- Job progress pictures

- Detailed project schedules

- Site plans

Quality Control

Consultant and/or Manufacturer Testing

- Moisture testing, adhesion testing, material thickness Mil thickness testing

- A quality plan Is created for every project detailed for the type of work

Quality Inspections

- Punchlist walks completed internally

Safety

Safety is embedded into our culture. We engineer jobs to have low risk so we have no injuries.

Random safety Inspections

Job Safety Plan

Scaffolding

Overhead protection

Dust Control

Request a Quote

and we will be in touch within 24 hours